모든 제품

-

마틴처음 우리는 용성 알루미늄과 협력했습니다, 상품의 배달 시간 또한 매우 매우 빠르고 사업관리인 것은 전문적이기 때문에, 우리가 그것이 매우 쉬운다고 생각했습니다. 그는 내가 약간의 기술적 문제를 해결할 수 있도록 도와 주었습니다. 상품은 매우 좋은 상품 중 2021.1.20과 품질에 받아들였습니다!

마틴처음 우리는 용성 알루미늄과 협력했습니다, 상품의 배달 시간 또한 매우 매우 빠르고 사업관리인 것은 전문적이기 때문에, 우리가 그것이 매우 쉬운다고 생각했습니다. 그는 내가 약간의 기술적 문제를 해결할 수 있도록 도와 주었습니다. 상품은 매우 좋은 상품 중 2021.1.20과 품질에 받아들였습니다! -

엘리스 Su우리의 회사와 용성 알루미늄은 거의 3년 동안 협력했습니다. 우리는 공장을 방문했습니다, 용성이 전문적 알루미늄 재료 공급부라고, 우리가 그들의 공장에서 알루니늄 스트립을 구입했고, 장기 협력을 유지할 것입니다.

엘리스 Su우리의 회사와 용성 알루미늄은 거의 3년 동안 협력했습니다. 우리는 공장을 방문했습니다, 용성이 전문적 알루미늄 재료 공급부라고, 우리가 그들의 공장에서 알루니늄 스트립을 구입했고, 장기 협력을 유지할 것입니다. -

조이우리는 용성 알루미늄으로부터 알루미늄 써클을 구입하고, 그들을 가나에게 선적하. 우리는 2년간 그러한 협력 관계를 유지되게 하고 매달을 수송하여야 합니다. 협력의 과정에서, 모든 링크는 매우 효율적이고 계정 관리자가 우리가 빨리 문제를 해결할 수 있도록 도와 줄 것입니다. 우리는 매우 믿을만한 공급업체를 발견한 것에 행복합니다.

조이우리는 용성 알루미늄으로부터 알루미늄 써클을 구입하고, 그들을 가나에게 선적하. 우리는 2년간 그러한 협력 관계를 유지되게 하고 매달을 수송하여야 합니다. 협력의 과정에서, 모든 링크는 매우 효율적이고 계정 관리자가 우리가 빨리 문제를 해결할 수 있도록 도와 줄 것입니다. 우리는 매우 믿을만한 공급업체를 발견한 것에 행복합니다. -

아민 마즈루텀우리는 총 용성 알루미늄으로부터의 거의 500 톤의 엠보싱된 색 알루미늄 코일을 구입했습니다. 품질은 안정적이고 배달 시간이 빠릅니다. 내 고객들은 내 제품에 매우 만족합니다. 우리는 계속해서 용성 알루미늄과 협력할 것입니다.

아민 마즈루텀우리는 총 용성 알루미늄으로부터의 거의 500 톤의 엠보싱된 색 알루미늄 코일을 구입했습니다. 품질은 안정적이고 배달 시간이 빠릅니다. 내 고객들은 내 제품에 매우 만족합니다. 우리는 계속해서 용성 알루미늄과 협력할 것입니다.

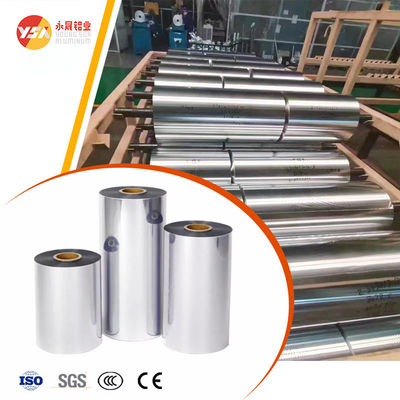

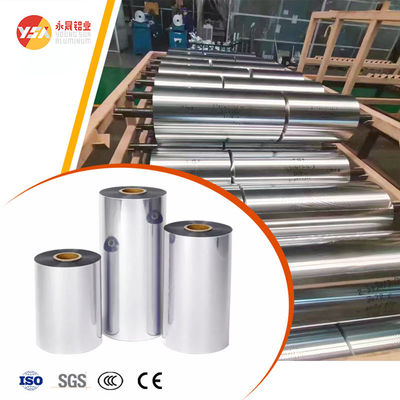

8011 가구용 알루미늄 엽 포일 포일 포일 알루미늄 엽 덤보 롤 식품용

무료샘플과 쿠폰을 위해 나와 연락하세요.

왓츠앱:0086 18588475571

위챗: 0086 18588475571

스카이프: sales10@aixton.com

만약 당신이 어떠한 관심도 가지면, 우리가 24 시간 온라인 도움말을 제공합니다.

x제품 상세 정보

| 합금 | 1235, 1145, 8011, 8021, 8079 등 | 성질 | O, H18 |

|---|---|---|---|

| 두께 | 0.004-0.2mm | 너비 | 200-1700mm |

| 길이 | 고객 요구 사항 | 내 직경 | 75/150mm |

| 사용 | 포장, 의료 건설 식품 | 기준 | ASTMB209, EN573-1S |

| 포트 | Qingdao, 상하이, Tianjin | 견본 | 무료 |

| 강조하다 | 세대 알루미늄 포일 뭉치,대용량 알루미늄 필름,식품 등급 알루미늄 호일 |

||

제품 설명

8011 가구용 알루미늄 필름 덤보 롤

가정용 및 상업용 식품 포장용으로 설계된 고급 식품급 알루미늄 엽록물 롤.

제품 특성

주요 특징

- 원료 알루미늄 합금에서 고온 소화 및 살균으로 만들어집니다.

- 밀도가 높은 산화물 표면 층은 화학적 안정성과 식품 안전성을 보장합니다.

- 박테리아 성장 을 억제 하고 유해 물질 을 함유 하지 않는다

- 폭 넓은 온도 저항 범위 (-20°C ~ 250°C)

- 고온 살균에 적합한 안정적인 분자 구조

- 빛과 기체에 대한 우수한 장벽 특성

- 음식의 맛을 보존하고, 수분을 유지하며, 보관기간을 연장합니다.

- 재생 과정에서 에너지 소비가 낮아 재활용 가능

- 인쇄 및 표면 처리와 호환되는 밝은 금속 광택

- 가볍고, 휴대 하기 쉬우며, 접으면 균열 되지 않습니다

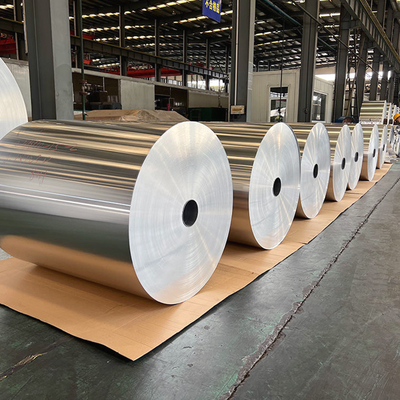

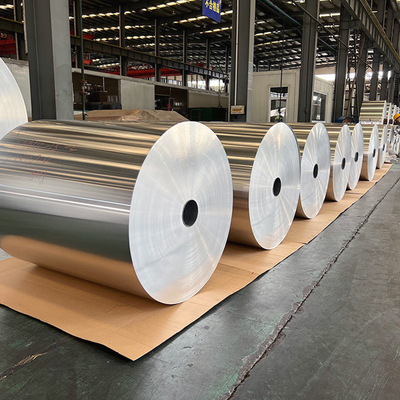

알루미늄 포일 생산 과정

제조 과정은 400~500°C까지 잉크를 가열하고 약 3mm의 두께까지 뜨거운 롤링으로 시작됩니다.그 후 350~450°C에서 굽혀 부드럽게 만든다.그 후 필름은 표준 너비로 자르고 품질을 검사하고 배송을 위해 포장됩니다.

웅성 공장 장점

대량 생산:비용 최적화 동시에 상당한 시장 수요를 충족

첨단 기술:성능 향상을 위한 새로운 프로세스를 개발하는 전문 팀

품질 보장:ISO 및 FDA 표준을 준수하는 포괄적 인 제어 시스템

사용자 정의 서비스:합금 성분, 두께, 너비 및 표면 처리에 맞춘 솔루션

첨단 기술:성능 향상을 위한 새로운 프로세스를 개발하는 전문 팀

품질 보장:ISO 및 FDA 표준을 준수하는 포괄적 인 제어 시스템

사용자 정의 서비스:합금 성분, 두께, 너비 및 표면 처리에 맞춘 솔루션

제품 사양

| 제품 | 합금 | 온도 | 너비 (mm) | 두께 (mm) | 신청서 |

|---|---|---|---|---|---|

| 의약품 포일 | 8011 8021 8079 | O-H18 | 100~1600 | 00.01-0.2 | 의약품 캡슐 포장, 봉지 |

| 배터리 껍질 포일 | 8021 8079 1235 | 오 | 100~1600 | 00.015-0.055 | 배터리 소프트 팩 포일 |

| 전극 응압기 필름 | 1070 3003 1100A | H18 | 100~1600 | 00.016-0.4 | 전자 부품 |

| 테이트 포일 | 1060 8011 1235 | O-H18 | 100~1600 | 00.016-0.4 | 냉장고, 자동차, 전자 산업 |

| 식품 포장용 포일 | 1060 3003 8011 1100 3004 8021 | H24 H22 H18 O | 300-1100 | 00.01-0.2 | 식품 포장 용도 |

| 열 밀착 필름 | 8011 8079 1235 | O/HO | 100~1600 | 00.025-0.1 | 식품 및 의약품 포장 |

주요 합금의 성능 비교

| 합금 등급 | 주요 구성 | 강도 | 유연성 | 부식 저항성 | 핵심 응용 프로그램 |

|---|---|---|---|---|---|

| 1235 | 99.35% 알 + 시, 페 | 낮은 | 매우 높습니다. | 높은 | 식품/의약품 유연 포장, 알루미늄 엽지 |

| 1145 | 99.45% 알 + 시, 페 | 낮은 | 매우 높습니다. | 높은 | 높은 유연성 포장 |

| 8011 | 알 + 0.7-1.1% Fe + 0.5-0.9% Si | 중간 | 중간 | 높은 | 식용 상자, 약품 블리스터, 병 캡 가스켓 |

| 8021 | 알 + 0.8-1.2% Fe + 0.5-0.9% Si | 중간 | 중간 | 높은 | 극 얇은 포장재 |

| 3003 | 알 + 1.0-1.5% Mn | 높은 | 중간 | 높은 | 산업용 포장재, 리?? 배터리 필름 |

제품 이미지

제품 응용

추천된 제품